1. Ifilimu yomaleko omnye

Kufunwa ukuba ibe sobala, ingabi netyhefu, ingabonakali, ibe ne-heat-sealing bag-making, ukushisa kunye nokumelana nokubanda, amandla omatshini, ukuxhathisa igrisi, ukuxhathisa iikhemikhali, kunye nokuchasana nokuthintela.

2. Isikhwama se-aluminium foil

I-99.5% ye-aluminiyam ye-electrolytic ecocekileyo iyanyibilika kwaye icinezelwe kwi-foil nge-calender, efanelekileyo njenge-substrate yokupakisha iplastiki eguquguqukayo.

3. Ifilimu ye-aluminiyam ephuphumayo

Phantsi kwevacuum ephezulu, iintsimbi ezibilayo ezisezantsi, ezifana ne-aluminiyam, ziyanyibilika kwaye zibe ngumphunga kwaye zifakwe kwifilimu yeplastiki kwigubu lokupholisa ukuze zenze ifilim ene-aluminiyam ekhazimlayo entle yesinyithi.

4. Ukwaleka kwesilicon

Isixhobo sokupakisha esingafihliyo esineempawu zesithintelo eziphezulu kakhulu ezaphuhliswa ngeminyaka yoo-1980, ekwabizwa ngokuba yi-ceramic coating.

5. I-Glue (eyomileyo / emanzi) ifilimu edibeneyo

Iifilimu ze-Monolayer zineenzuzo ezithile kunye nokungalunganga okungokwemvelo.Indlela yefilimu edibeneyo emanzi: enye i-substrate ifakwe ngeglue kwaye i-laminated enye ifilimu ye-substrate, kwaye yomiswe kwaye iphiliswe.Ukuba yinto engeyiyo i-porous, ukomiswa kweglue kunokuba nzima kwaye umgangatho we-membrane edibeneyo uya kuncipha.Indlela yokomisa i-lamination: Gcoba i-adhesive kwi-substrate, vumela i-adhesive yome kuqala, uze ucinezele kunye ne-laminate ukuze udibanise iifilimu ze-substrates ezahlukeneyo.

6. Ifilimu edibeneyo yokugquma i-Extrusion

Kwi-extruder, i-thermoplastic iphonswa nge-T-die kwiphepha, i-foil, i-substrate yeplastiki ukuba ifakwe, okanye i-resin ekhutshiweyo isetyenziswe njenge-binder ephakathi, kwaye enye i-substrate yefilimu ishushu.Izinto eziphathekayo zixinzelelwe kunye ukuze zenze "isandwich" ifilimu edibeneyo.

7. Ifilimu edibeneyo ye-Coextrusion

Ukusebenzisa extruders ezimbini okanye ezintathu, ukwabelana die composite, laminates phakathi thermoplastic eziliqela ehambelanayo ukuvelisa films multilayer okanye sheets.

8. Ifilimu yesithintelo esiphezulu

Ibhekisela kwizinto ezinobunzima be-25.4μm phantsi kweemeko ze-23 ° C kunye ne-RH65%, izinga lokuhambisa i-oksijeni lingaphantsi kwe-5ml / m.2·d, kwaye izinga lokuhambisa ukufuma lingaphantsi kwe-2g/m2·d.

9. Ukugcinwa ngokutsha kunye nefilimu yokuvala inzala

I-ethylene gas adsorption membrane, ukongeza i-zeolite, i-cristobalite, i-silica kunye nezinye izinto kwi-membrane inokufunxa igesi ye-ethylene ekhutshwe ziziqhamo kunye nemifuno kwaye inqanda ukuvuthwa kwabo ngokukhawuleza.

Ifilimu ye-Anti-condensation kunye ne-fogging, indawo yangaphakathi yefilimu yokupakisha yeziqhamo eziluhlaza ine-condensation eninzi kunye ne-fogging, ekulula ukubangela i-mildew ekudleni.

Ifilimu ye-Antibacterial, yongeza i-zeolite yokwenziwa (SiO2+Al2O3) kunye nomsebenzi wotshintshiselwano lwe-ion kwizinto zeplastiki, kwaye emva koko ukongeza isihluzi se-inorganic esine-ion zesilivere, utshintshiselwano lwe-ion sodium yesilivere iba yi-zeolite yesilivere, kwaye umphezulu wayo uneempawu zokulwa ne-antibacterial.

Ifilimu ye-infrared-fresh-regiving ifilimu ixutywe kunye ne-ceramic filler kwifilimu yeplastiki, ukwenzela ukuba ifilimu inomsebenzi wokuvelisa imisebe ye-infrared ekude, engakwazi ukutshabalalisa kuphela, kodwa iphinde isebenze iiseli kwisiqhamo esiluhlaza, ngoko ke. inomsebenzi wokugcina ubutsha.

10. Ifilimu yokupakisha ye-Aseptic

Ikakhulu isetyenziswa kwimveliso yokupakishwa kwe-aseptic yokutya kunye namayeza, kuyafuneka ukuba ibe: ukuxhathisa inzala;iipropathi zomqobo ophezulu kunye namandla;ubushushu obuhle kunye nokumelana nokubanda (-20 ℃ akubi brittle);ukuxhathisa inaliti kunye nokumelana nokugoba okulungileyo;Ipateni eprintiweyo ayisayi konakaliswa kubushushu obuphezulu bokuvala inzala okanye ezinye iindlela zokuvala inzala.

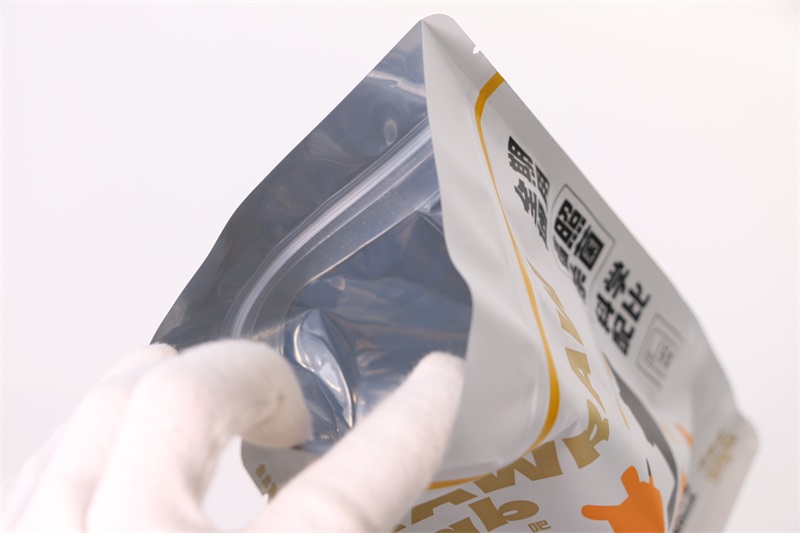

11. Ibhegi yokupheka enobushushu obuphezulu

Ngeminyaka yee-1960, i-US Naval Research Institute yaqala yavelisa kwaye yayisebenzisa ekutyeni kwe-aerospace.Emva koko, iJapan yakhawuleza ukuyikhuthaza kwaye yaphuhlisa kwaye yayisebenzisa kwiintlobo ezahlukeneyo zokutya okulula.Iingxowa zokupheka eziphezulu zokushisa zingahlulwa zibe luhlobo olucacileyo (kunye neshelufu engaphezulu konyaka omnye) kunye nohlobo olungabonakaliyo (kunye neshelufu engaphezulu kweminyaka emibini), uhlobo oluphezulu lomqobo kunye nohlobo oluqhelekileyo.Ngokweqondo lobushushu lokuvala inzala, yahlulwe yaba yibhegi yokupheka yobushushu obuphantsi (100℃, 30min), ibhegi yokupheka yobushushu obuphakathi (121℃, 30min), ibhegi yokupheka yobushushu obuphezulu (135℃, 30min).Isixhobo sangaphakathi se-retort isikhwama senziwe ngeefilimu ezahlukeneyo ze-PE (LDPE, HDPE, MPE), i-CPP okanye i-IPP evuthelweyo, njl.

Iingenelo eziphambili zeengxowa zokupheka ezishushu:

①Ukushisa okuphezulu kokupheka kunokubulala zonke iibhaktheriya, i-121℃/30min inokubulala zonke iibhaktheriya ze-botulinum;

②Inokugcinwa kwiqondo lobushushu begumbi ixesha elide ngaphandle kwefriji, kwaye inokutyiwa ibanda okanye ishushu;

③ Izinto zokupakisha zineempawu ezintle zokuthintela, akukho ngaphantsi kokutya okunkonkxiweyo;

④Umva ukuprintwa, ushicilelo oluhle kunye nokuhombisa;

⑤ Inkunkuma kulula ukuyitshisa.

12. Ifilimu yokupakisha yobushushu obuphezulu

Indawo yokunyibilika kwezinto eziphathekayo ingaphezulu kwe-200 ° C, efanelekileyo kumandla aphezulu aqinileyo / izitya ezithambileyo.

13. Ifilimu yeplastiki eyonakaliswayo

Iimveliso zeplastiki ezonakeleyo zinokwahlulwa zibe yifotodegradation, biodegradation, photodegradation and biodegradation ngokwendlela yokubola.

14. Fudumeza ifilimu eshwabeneyo

Izinto eziphathekayo ziyi-PP, i-PVC, i-LDPE, i-PER, i-nylon, njl. Okokuqala khupha ifilimu, kwiqondo lokushisa elingaphezu kweqondo lokushisa elithambileyo (indawo yokutshintsha iglasi) kwaye ngaphantsi kweqondo lokushisa elinyibilikayo, kwi-elastic state, sebenzisa i-synchronous okanye i-step-step. i-flat-die stretching method, okanye i-calendering method, okanye i-solvent Indlela yokuphosa yenza i-directional stretching, kwaye iamolekyu ezolulayo zipholile ngaphantsi kwendawo yokuguqula iglasi kwaye ivaliwe.

Ixesha lokuposa: Apr-25-2022